HOW TO WELD BANDSAW BLADE - 4 EASY STEPS TO REUSING BROKEN BANDSAW BLADES

How to weld Bandsaw Blade – 4 easy steps to reusing broken bandsaw blades

Bandsaw blades are indispensable for cutting complex curves and forms in metal and wood, as any craftsman will attest. Bandsaw blades are expensive to replace because they shatter easily from use and deterioration. Fortunately, you can save a lot of money in the long run by welding the damaged bandsaw blades together. Learn how to weld and reuse bandsaw blades in just four simple stages with our step-by-step guide.

So why do we need to join bandsaw teeth together?

Bandsaw blades are incredibly important in the metalworking and woodworking industries, but they can also be quite pricey to repair. In addition to saving money, welding broken bandsaw blades can help decrease waste, which is good for the environment. You can save time and effort looking for the best blade for your cutting requirements by welding the blades together.

What You'll Need in Terms of Equipment

You'll need the following equipment and supplies to solder bandsaw blades:

- Broken Bandsaw Blade

- Machine for welding

- Welding rods

- Angle Grinder

- Protective equipment (welding mask, gloves, and apron)

Methods for Welding a Bandsaw Knife

Sharpen the blade

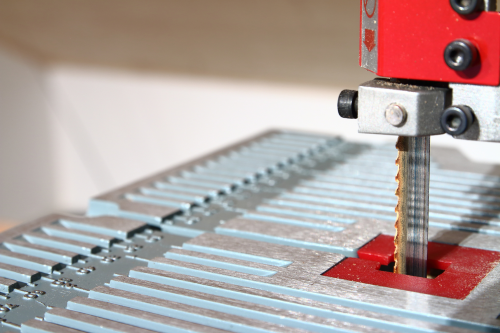

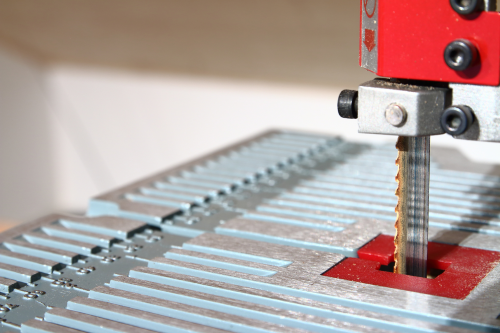

The first order of business is to get the bandsaw blade ready for soldering. Remove any rust or debris from the fractured sections of the blade using an angle grinder. Make sure there are no burrs or rough points on the blade.

Set the blade in place

After the blade has been honed and sharpened, it can be positioned for soldering. The blade ends must be brought into proper alignment and clamped back together. Verify that the fractured ends of the blade are aligned, and that the blade is straight before continuing.

Blade Welding

Start welding the shattered halves of the blade back together using the welding equipment and the proper welding wire. Weld the fractured ends of the blade together by feeding welding wire into the joint and heating it until it melts and fuses. Keep welding until the joint is finished, paying close attention to maintaining a uniform, smooth weld.

Complete the welded edge

After you're done welding, use an angle grinder to get rid of any sharp corners or leftover welding wire. Check that the blade is clean and free of any sharp points that could cause harm.

Hints and Techniques

- Using the right welder wire is crucial when welding bandsaw blades. To find out what kind of wire should be used with your welder, you should look at the instructions.

- Protect yourself from the sparks and heat by always wearing a welding helmet, gloves, and an apron.

- Make sure the shattered blade ends are lined up straight before fusing them back together.

- Before trying to weld a broken bandsaw blade, it is recommended that you practice on a scrap piece of metal.

Conclusion

Rather than throwing away a damaged bandsaw blade, you can easily repair it by welding. If you are in the market for a high-quality bandsaw blades supplier Dubai, AFH Tools Company in Dubai is an excellent choice.